How Efficient Vacuum Belt Filter Press Be!

The vacuum belt filter press is an efficient solid-liquid separation device that utilizes vacuum pressure (0.04-0.07 MPa) to drive the separation process. Under the influence of this vacuum, the liquid in the slurry is drawn through the filtration medium (filter cloth), while the solid particles are retained by the medium, thus achieving the separation of liquid and solid.

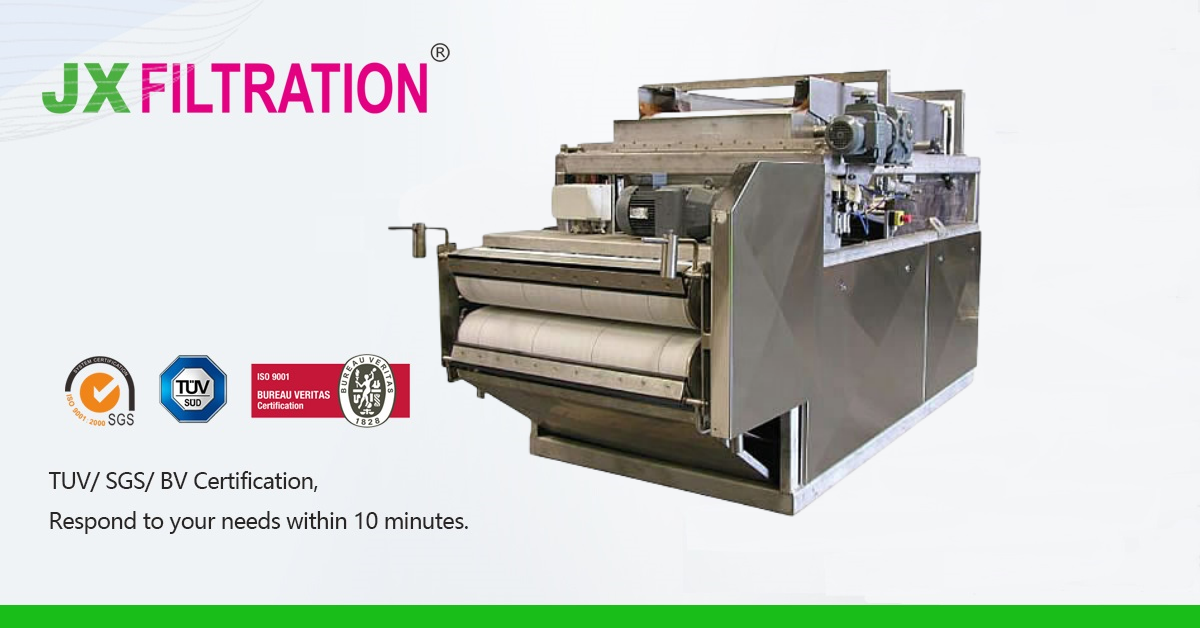

With a horizontal filter segment arrangement, the vacuum belt filter press can continuously perform various operations such as filtration, washing, drying, and filter cloth regeneration. This makes it highly efficient for a wide range of applications. The rubber belt version, in particular, offers excellent advantages such as high filtration efficiency, large production capacity, superior washing effect, low moisture content in the filter cake, flexible operation, and low maintenance costs.

The vacuum belt filter press is widely used across industries such as metallurgy, mining, chemicals, papermaking, food processing, pharmaceuticals, and environmental protection. Its application is especially significant in the dehydration of gypsum in flue gas desulfurization (FGD), where it plays a crucial role in ensuring optimal performance and environmental sustainability.

Whether you need high-capacity filtration or effective solid-liquid separation in demanding industries, the vacuum belt filter press proves to be a reliable and cost-effective solution.

Any requirements, contact us now!

Grace

Email: grace@filtrationchina.com

Mobile/Whatsapp/WeChat: +86 17269571160