Sludge Dewatering with Belt Filter Press Technology

The belt filter press has become a widely trusted solution for sludge dewatering across municipal and industrial wastewater treatment applications. Its continuous operation, energy efficiency, and reliable performance make it an ideal choice for facilities aiming to reduce sludge volume and lower disposal costs.

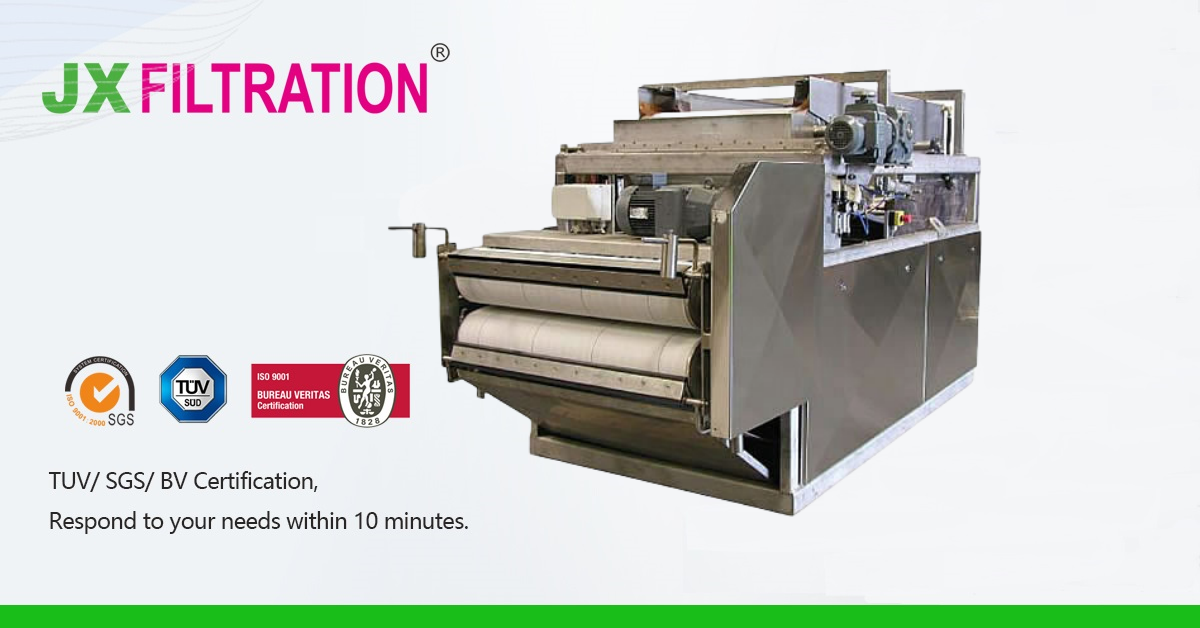

At the heart of the system is a simple yet effective mechanical design: sludge is conditioned with polymer and evenly distributed onto a moving belt. As it passes through a series of rollers under increasing pressure, water is squeezed out, resulting in a solid cake with significantly reduced moisture content. The filtrate is collected and returned for further treatment, while the dewatered solids are discharged for disposal or reuse.

One of the key advantages of the belt filter press is its low operating cost. Compared to thermal drying or centrifuge methods, it consumes less energy and requires minimal maintenance. Its compact footprint also makes it suitable for retrofitting into existing plants or for installations with space constraints.

Modern belt filter presses are designed with user-friendly controls and easy-access maintenance points. They can be customized with various belt widths, roller configurations, and automation levels to meet specific sludge characteristics and capacity needs.

Whether you’re handling municipal sludge, food processing waste, pulp and paper by-products, or chemical sludge, the belt filter press offers a practical, reliable, and cost-effective dewatering solution.

For more information or to request a quote tailored to your project, feel free to contact us. We’re here to help you optimize your sludge management process.

Any requirements, contact us now!

Grace

Email: grace@filtrationchina.com

Mobile/Whatsapp/WeChat: +86 17269571160