How to Select Right Model Volute Press?

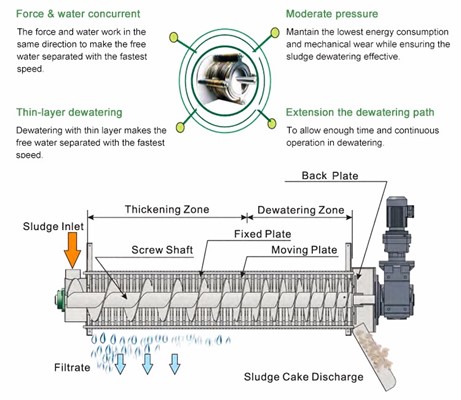

The Volute Press uses the automatic renewal cake filtration technology instead of the traditional filter screen filtration, and its own renewal cake filtration technology ensures the continuous and stable mud-water separation effect of the dewatering machine.

It is a new type of solid-liquid separation equipment, which realizes the extrusion and dewatering of sludge through the strong squeezing pressure generated by the change of screw diameter and pitch, and the tiny gap between the moving ring and the fixed ring.

How to select the model?

- The absolute dry sludge treatment capacity of Volute Press depends on the diameter and number of the main body of the volute.

The first two digits indicate the diameter of the main body of the volute, and the last one indicates the number of the main body of the volute, e.g. JXDL301 indicates the diameter of the main body of the stacked screw is 300mm, and the number of the main volute is 1 unit. - The absolute dry sludge (DS) of the Volute Press is the sludge that theoretically does not contain water. If the nature and concentration of sludge are not clear, it is recommended to use the average value of absolute dry sludge treatment capacity to calculate. Example: When the concentration of sludge mixture is 2%, the sludge mixture treatment capacity of JXDL312=100kg/h÷2%=5m3/h.

Calculation formula: The amount of sludge mixture treatment capacity = the amount of dry sludge treatment capacity ÷ the sludge concentration

- The height of the shaftless screw conveyor or feed hopper can be set with reference to the height of the bottom of the sludge cake discharge outlet from the ground.

- Since the main body of Volute Press has the function of self-cleaning, only normal pressure water (0.1~0.2Ma) is needed to implement regular spraying by normally closed solenoid valve.

- The replacement cycle of wearing parts of Volute Press is an approximate value. In actual operation, the type of sludge, treatment method, operation adjustment condition and daily operation time will affect the replacement cycle of wearing parts.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160