What is Plate and Frame Filter Press?

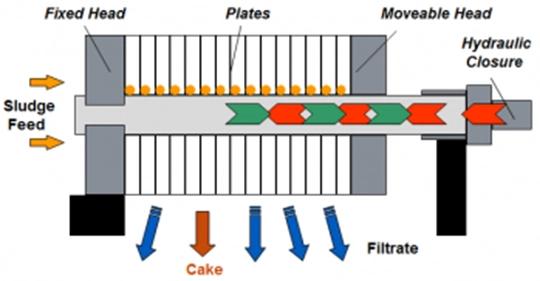

The plate and frame filter press is composed of filter plate and filter frame arranged to form a filter chamber (the filter plate is a vertical plane, the filter frame is an empty frame, and a filter plate and a filter frame are combined to form a complete filter chamber).

Working principle

Each group of filter plate and filter frame has a filter cloth in the middle, and the filter plate and filter frame are pressed together with the pressing end, so that a filter chamber is formed between the filter plate and the filter plate. The material flows in from the inlet, the water is discharged from the outlet of filtrate through the filter plate, the mud cake accumulates on the filter cloth inside the frame, and the mud cake can be easily peeled off after the filter plate and frame are released.

The plate and frame filter press is suitable for concentration of solid particles generally less than 10%, and the operating pressure is generally 0.3 to 0.6 MPa, with special ones up to 3 MPa or higher. The filtration area can be increased or decreased with the number of plates and frames used. The plate and frame are usually square, the inner length of the filter frame is 320-2000mm, the frame thickness is 16-80mm, and the filtering area is 1-1200㎡. The plate and frame are pressed by manual spiral, electric spiral and hydraulic pressure.

Features

- Plate and frame filter press in the late stage of filtration, the flow rate is very small, and the pressure is high, which can greatly reduce the energy consumption of operating power and play an energy-saving role.

- Adopting low-pressure filtration and high-pressure pressing, it can greatly shorten the whole filtration cycle and save labor time.

- Complete the diaphragm pressing function in a very short time, not only high efficiency, and can save power consumption to a large extent.

- Improve the degree of mud cookie, reduce the rate of mud cake, diaphragm press to the end of the static filtration of the filter cake for the second press, so that the structure of the filter cake rearrangement, density increased, so as to replace a part of the water, improve the dryness.

- Strong corrosion resistance, can meet the solid-liquid separation requirements of different industries, basically applicable to all solid-liquid separation operations.

- PLC and human-machine interface control can be configured to greatly reduce manual labor intensity and improve the efficiency of solid-liquid separation.

- The diaphragm filter plate has good sealing performance and other characteristics.

Application

Plate and frame filter press is generally suitable for materials with low solid content and small solid granularity, and is generally used more in the oil and grease industry and pharmaceutical industry, and can add filter paper as a kind of fine filtration.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160